This work introduces a bilevel optimization approach for robot kitting and demonstrates its ability to reduce both overall task time and idle times for a furniture assembly task. The optimization enables the robot to deliver usable kits just in time by performing task segmentation and scheduling in concert with kit arrangement. This paper is published at the 31st IEEE International Conference on Robot & Human Interactive Communication (RO-MAN) 2022.

The full paper can be accessed here.

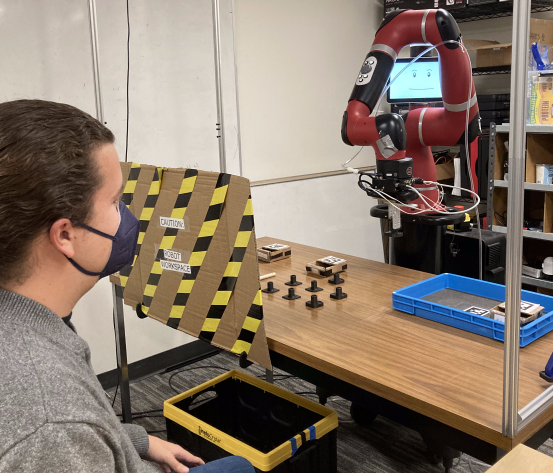

Abstract: Kitting refers to the task of preparing and grouping necessary parts and tools (or “kits”) for assembly in a manufacturing environment. Automating this process simplifies the assembly task for human workers and improves efficiency. Existing automated kitting systems adhere to scripted instructions and predefined heuristics. However, given variability in the availability of parts and logistic delays, the inflexibility of existing systems can limit the overall efficiency of an assembly line. In this paper, we propose a bilevel optimization framework to enable a robot to perform task segmentation-based part selection, kit arrangement, and delivery scheduling to provide custom-tailored kits just in time—i.e., right when they are needed. We evaluate the proposed approach both through a human subjects study (n=18) involving the construction of a flat-pack furniture table and shop-flow simulation based on the data from the study. Our results show that the just-in-time kitting system is objectively more efficient, resilient to upstream shop flow delays, and subjectively more preferable as compared to baseline approaches of using kits defined by rigid task segmentation boundaries defined by the task graph itself or a single kit that includes all parts necessary to assemble a single unit.